BLOG

In the Kelly Concrete blog we'll keep you updated about new and improved concrete placing and finishing techniques, new and improved concrete products and tools being used, or maintenance and care strategies. To top it off we will share pictures of recent projects, or will keep you up to date on what is happening within the walls of Kelly Concrete!

It's time for you to either update your current concrete driveway or expand it in a myriad of ways. You may not fully understand this process, however, before you attempt a DIY project. We strongly suggest that you never try to install a driveway on your own without help but should, instead, get the best concrete contractors in Iowa City, Cedar Rapids, and Dubuque, Iowa . These professionals can help you better understand your pouring needs and avoid unnecessary complications as well. They Help Plan Every Element Properly When you're starting a concrete project, you're going to have to do a lot of planning that you may not feel comfortable doing. This factor is common because these projects require a lot of careful work that provides home and business owners with the most reliable possible design and execution. And trying to do these steps on your own may prove disastrous if you don't take the proper steps to make sure that things go as smoothly as possible. Thankfully, concrete contractors can help in this situation. For example, they'll start by figuring out what kind of concrete your project needs and choose a type that meets your needs fully. Often, this process includes finding specialized materials that can be used to update the structure of your driveway or any kind of concrete project. Usually, you'll need to work with these contractors to identify the best functional materials and create a plan that makes it easier for them to lay a driveway, such as knowing when to put up various structural elements. In this way, your contractors can make sure that everything is appropriately prepared long before any concrete is poured. For example, they will dig out the area where the concrete must be poured, add protective guiding elements along the sides of the pour area to give it shape, and perform other steps to keep your project secure. Thankfully, these professionals can also handle this process for any other paving project that you may have coming up in the future. Hiring Professionals Saves You Money Here's something that may be hard for you to believe – hiring professionals ultimately saves you money on your concrete installation project. We can understand if it is hard to accept this because people are taught that DIY work is an excellent choice for those on a budget. And if you have the skills necessary to pour concrete, you may save some money doing it yourself. However, we find that most people either lack these skills or overestimate their capabilities in many unfortunate ways. For example, you may think that pouring concrete is as simple as mixing the materials and spreading this pavement on the ground. This myth is one that many people quickly discover is far from the truth. Sadly, concrete is by no means easy to install because there are elements that you may not consider. Do you know what temperature is perfect for concrete pouring? Or how much water to add to your mix to ensure that it pours easily? Probably not, and you wouldn't be alone. You may be able to use DIY videos to mix concrete and get results that aren't too bad. But what happens if your concrete dries and immediately starts experiencing damage? Then, you're going to have to contact concrete contractors who can handle these repairs for you. When you do, you're likely to find that the repairs cost at least as much as it would have cost to install the slab for you. In some cases, it may cost more because they may need to remove the concrete first. Contractors Manage Other Project Aspects When a contractor starts working on your home, they will take many steps to ensure that things go as smoothly as possible. After the planning process is over, they will handle the execution of the pouring of your concrete. While you may think that this process would be relatively simple and easy to handle, that isn't always the case. History shows that many people struggle to control a concrete pour in a DIY fashion and may need high-quality help to get the protection that they need here. For example, some may not understand that they need to cut the surface of their concrete after a pour to create expansion cracks that prevent damage to their slabs. Typically, these cuts have to be done at pretty specific points along the surface of a driveway. For example, some may need to be made every 5-10 feet, depending on many factors. Most homeowners don't understand these factors off-hand and need concrete contractors to avoid complications. Just as importantly, these experts will manage other aspects that you might not consider. For example, they will help plan the transportation of the concrete, mix it for you, check it for excess moisture, and ensure that it is as secure as possible. By taking these precautionary steps, these contractors make your concrete more durable and prevent severe and long-lasting damage. Just as importantly, they also make sure that you are satisfied with your project and don't run into any issues down the road. Contractors Have Insurance Lastly, concrete contractors have what you probably do not – insurance for your concrete project. That's because all contractors must insure their work, particularly if they are licensed, though some may not. And unless you're willing to spend money on insurance for one project – and who would blame you if you didn't? – you won't have insurance for your DIY pour. So what's the big deal? Well, if a contractor makes a mistake during a pour, they don't turn to you for more cash – instead, they activate their insurance policy. And this is a huge benefit because it helps to get these mistakes fixed without costing you any cash. But what if you make a mistake on a DIY project without insurance? You are paying for the repairs out of your project. Even better, most pavers also have warranties on their projects that help to ensure that you don't run into issues down the road. The lengthy of these warranties will vary but there's one thing that does not – your DIY driveway will have NO warranty to cover any pouring problems. As a result, it is a good idea to get contractors to handle this need for you. Get Help From Us As you can see, the best concrete contractors Coralville, Waterloo, and Cedar Falls, Iowa has to offer can provide you with many benefits that you can't get in any other way. So please feel free to contact us at Kelly Concrete today to learn more about how we can help you. Our experts have years of experience in this field and fully understand the demands that it puts on you. And we'll do what we can to help you get the necessary help for your high-quality driveway, parking, lot, or sidewalk project.

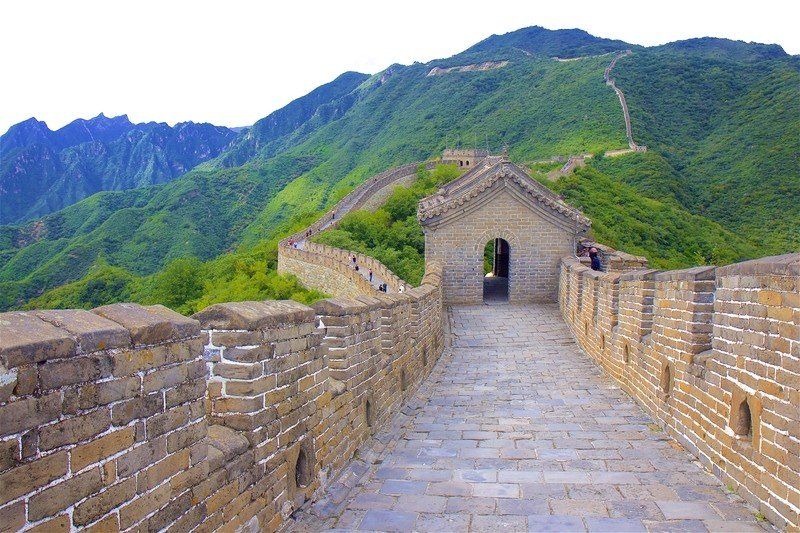

Cement and concrete have been used by humans for thousands of years. And for good reason — these materials are incredibly versatile, durable, and economical. When made correctly, concrete can be waterproof, stormproof, and fireproof, and it only gets stronger with time, which is why so many structures built with cement and/or concrete are still around today.

Over the years, you've worked with many types of concrete in Cedar Rapids, Marion, Iowa City, North Liberty, Dubuque, Coralville, Waterloo, and Cedar Falls, Iowa but aren't sure how to keep it lasting as long as possible. Thankfully, the following tricks can help your pour last as long as possible. These tricks and techniques are all things that we at Kelly Concrete have learned over the years. As a result, we can provide you with some of the best pours that you'll find anywhere on the market today. Proper Slab Thickness When you're preparing to pour your concrete , it can be hard to know how thick you want it poured. While professionals can help you make this decision, you ultimately have to make it on your own. As a result, you need to make sure that you fully understand this factor to ensure that things go smoothly. Thankfully, there is a pretty simple solution here – four inches is usually good enough for most situations. However, there may be sections that need to be thicker than this four inches, depending on the nature of your driveway or parking lot. For example, you should be able to get away with four inches in most driveways but may need to tweak up your approach if there is a high-traffic area that often wears down more quickly. Add an extra inch or so to these areas to ensure that you get the most protection possible for your driveway or parking lot. Can you go thinner than four inches? Probably not because, at that point, you're putting too much stress on the surface. Though it should distribute fairly evenly and minimize damage to most areas, not taking the time to add at least four inches ultimately costs you more money by putting more strain on your pour. As a result, it is smart to aim for four inches or more, particularly if you want your slab to last longer or resist wear and tear better. Dealing With Clay Soil The toughest thing about pouring is knowing what kind of soil upon which you'll be pouring. Unfortunately, there is a good chance that many types are going to be made quite slowly of clay. Clay-heavy grounds are not great for pouring because they have a terrible tendency not to absorb water. They may also lack the kind of adaptability and flexibility that you need to make your pour as secure as possible. Thankfully, there are ways of dealing with this issue. For example, compacted earth can help to manage many of these issues by providing you with a more substantial base on which you can pour your concrete . However, you may also need to import a separate kind of support for clay to ensure that it doesn't affect your pour. We don't mean importing soil from overseas or anything like that but bringing in outside dirt that you can use as a supporting base for your pour and throughout the rest of the area. Typically, you're going to want looser earth that has minimal clay. However, you also want to avoid sand – sand moves too much and doesn't provide the support that you need. The balance here can be tricky to achieve, unfortunately, but doesn't have to be too hard to handle if you're smart and take the time to accurately assess the balance of your soil and make adjustments to ensure that it is as secure as possible for your needs. Proper Curing Steps When it comes to making sure that your pour is as secure as possible, curing is critically essential. This step is one that may seem like it would be easy – after all, you are mostly waiting for your concrete to dry. However, you need to make sure that you follow the proper steps to ensure that things go smoothly. Thankfully, success here isn't difficult if you understand what you're doing. For example, you need to make sure that you keep the surface warm and moist for as long as possible to ensure that the surface is as durable as possible. You don't need to water the driveway, as such, but should add a liquid membrane on the surface of the slab after it is finished. This step helps to prevent fast drying and makes sure that the surface cures at a speed that makes sense for you. Last tip here: try to only pour cement during warmer months, when freezing is least likely to happen. Unfortunately, freezing temperatures can complicate the curing process and cause premature damage to slabs that can be hard to repair. As a result, it is essential to pay attention to the weather and only work with cement when temperatures are at their most reasonable – this should help avoid severe damage. Proper Winter Management Lastly, it is vital to understand how to treat your concrete during your first winter with it. Sometimes, people don't fully grasp that winter is often the toughest time for their cement. That's because cold weather can impact the surface in a variety of ways and make it expand and contract in upsetting ways. Therefore, it is essential to take the time to manage this situation as smoothly as possible to avoid any issues. For example, you should keep salt or other chemical deicers off of your driveway. Using these too soon can cause the cement to expand and contract and may create real damage. You need to make sure that you avoid salt, in particular, by washing it off of your cars and your driveway if you bring it from other roads. The potential impact that it has on your driveway is that severe, unfortunately. Thankfully, you can avoid ice by using sand on your cement instead. Sand is a good choice because it doesn't cause the same kind of damage that you get with salt. And it doesn't trigger melting as quickly, either, which minimizes your damage potential. One final note: NEVER use fertilizer on your cement driveway as a deicer, even years later, because it is far too acidic and dangerous. Reach Out to Us for Help As you can see, the best concrete Cedar Rapids, Marion, Iowa City, North Liberty, Dubuque, Coralville, Waterloo, and Cedar Falls, Iowa has to offer doesn't have to be a significant challenge to pour. As long as you fully understand this unique process and how to perform it, it would help if you didn't have a hard time getting the high-quality pour that you deserve. So please don't hesitate to contact us today at Kelly Concrete to learn more. Our experts have years of experience and will help you succeed where others have failed.

Home and business owners with cement structural items may end up making mistakes that cause them to fail. Thankfully, the best concrete Cedar Rapids, Marion, Iowa City, and North Liberty, Iowa has to offer can help. These professionals will work with you to ensure that you aren't making common mistakes that can cause real damage to your cement structures. And at Kelly Concrete , we understand all of these processes and can do what is necessary to ensure that they don't end up adversely impacting you. Poor Structural Support When you add concrete to your home or business, you need to make sure that it gets the proper support. For example, there needs to be firm land underneath of it that supports it and keeps it from shifting. It would help if you also made sure that the underlayment is as durable as possible to avoid other problems. Unfortunately, many people don't take these steps and end up letting their surfaces degrade. WHen this happens, cracks and other problems will become rampant. Therefore, it is vital to make sure that your slabs are appropriately supported and strong enough to avoid severe damage. Talk to professionals about this process, including adding new structural elements beneath each slab. Doing so will help you get the help that you need to keep this structure secure and prevent serious cracks and other types of issues that may impact the surface. And if you have any slabs that may overhang or which may be in the air, it is essential to add support for them as well. This process can include adding columns to add extra strength to balconies and other items for your cement. Again, it would help if you talked to a professional about this process to ensure that you don't make any support mistakes that could cause damage to your cement slabs. Experts fully understand how to support your cement in a positive way. No Weather Support People who add cement or other items to their home may think that it can withstand the weather of all types without any protection. This mistaken concept is a real problem because cement and other materials can be very heavily damaged by temperature and weather changes. Understanding all of these problems and how to protect against them is critical as a way of keeping a home in great shape and avoiding damage that may spiral out of control unexpectedly. For example, you need to make sure that your concrete doesn't get profoundly affected by cold temperatures during the winter. This process includes adding a sealant to the surface that will keep it from expanding and contracting. Just as importantly, you need to make sure that you remove ice and snow and any moisture because this can further damage the surface of cement in multiple ways. Thankfully, you should be able to talk to professionals to get maintenance help if you need it. A variety of experts can provide the type of treatment necessary, such as cleaning your cement, eliminating various stains, and cleaning the surface from the mold. All of these steps can help to keep hot and cold temperatures, wind and rain, and snow from causing real damage on your cement surfaces. Failure to Repair Damage People often don't realize that a large amount of damage can severely impact their slabs if they aren't too careful. For example, structural damage can spread throughout concrete that causes it to fail and slowly crack. However, cement can also be impacted by fire, especially if it is allowed to sit on the surface for long enough. When this happens, the cement will warm up, expand, and could end up cracking throughout in various places. There are also other types of damage to watch for in cement, including blast damage, impact damage, and seismic problems. Though some of these issues are quite rare, they may still impact a slab. And the moment that an owner sees imperfection in their slabs, they need to do what they can to repair them. Even a small crack can spread very rapidly across the surface and sink deeper to become a real issue that may require professional help. Do small cracks need the help of experts to manage appropriately? That all depends on your experience with repairs. Some people will feel comfortable working with cement-repair tools and should be able to handle patching and other steps. However, others may not have the skills and feel uncomfortable with the process. As a result, you may want to reach out to an expert to see what to expect and ask for a price before going it on your own. Adding Too Much Weight People who build concrete or cement surfaces may think that they can add just about anything to them without causing any damage. And in many cases, they may be somewhat right. While not perfect, many slabs can support a surprisingly high level of weight. That said, there is also a chance that these slabs may end up cracking if the homeowner or business owner puts too much pressure on them in one place. For example, most slabs should be capable of support thousands of pounds across their whole surface. However, sustained pressure in one spot may cause cracks and other problems that rapidly spread throughout a slab. This problem is most common for commercial businesses that may own a large number of heavy vehicles. As a result, it is essential to move them around to avoid excessive weight-related damage. That said, even homeowners may cause this damage if they aren't too careful. As a result, it is vital to think of a cement surface as a very strong, but still crackable, item that requires a careful balance between too much weight and too little. Remember: the surface is designed to support thousands of pounds but may end up experiencing failure without proper preparation. Thankfully, this step isn't too hard to do correctly for most people. Getting Help Right Away As you can see, ensuring that you have the best concrete in Dubuque, Coralville, Waterloo, and Cedar Falls, Iowa doesn't have to be a significant hassle. However, you do need to make sure that you take the steps mentioned above to ensure that you don't experience any issues. You should also contact us at Kelly Concrete right away to get help. Our experts have years of experience in this field and fully understand its unique demands. And we'll do what is necessary to help keep your cement strong and stable for years to come.

Trying to market your business is often a tough task but can be done in many ingenious ways. For example, you can use the best stamped concrete Cedar Rapids, Marion, Iowa City, and North Liberty, Iowa have to offer to expand your potential branding opportunities. Doing so is a smart way of making people see your brand and logo whenever they visit and enhances your branding visibility. Branding Helps Spread Your Company Name A company succeeds based on a variety of different factors. The most obvious of these is the popularity and quality of their services and their products. However, you might be surprised to know that this is only one part of the equation. Any company worth its weight in gold spends just as much time focusing on its branding as it does on making sure that its products and services are excellent. In essence, branding is the process of creating an image that helps your company stand out from others. These steps often include marketing methods but also focus on concepts such as your mission objective – often called the M.O. – and other factors. A successful company blends all of these concepts, including elements like its logo, into a brand that is intelligent and successful. Thankfully, there are many different ways that you can brand your company. These include advertising, various types of community fundraisers, getting out in public, and much more. However, talented business owners utilize not only these methods by finding ways to make a company building brand itself. One of the best ways of doing this is by using stamped concrete to stand out in surprising ways. Concrete Provides a Unique Branding Possibility When you create a great logo that helps to sell your brand, you need to get it out to your customers in any way possible. Advertisements are one way to do this, but you also need to focus on ways that you can tweak your building and your company's facilities to drive the brand home further. There's no shame in utilizing your building in this way – look at how companies like McDonald's use a logo on their structure to enhance their brand. Concrete stamping provides a unique way for you to imprint your company logo – and by extension, your brand – into the minds of your customers. Stamped concrete is often considered one of the most attractive design elements of a facility and makes a company stand out from its peers. Just as importantly, your customers will see it and know that you spent the time to craft a high-quality look at your facility. As a result, concrete stamping is often one of the most ingenious and subtle ways to enhance your branding. It is particularly essential if your building feels somewhat bland or unattractive to you. If you think that your building doesn't catch the eye, your customers will likely think the same thing. Thankfully, stamping concrete is inexpensive and provides one of the easiest ways of decorating your business and its building. Many Areas Can Be Stamped The cool thing about stamped concrete is that it can be added just about anywhere in your facility. You can add it to the exterior to catch the eyes of people walking by your company. However, you can also add concrete stamps to areas inside of your building, as well. For example, you can stamp your concrete floor to create unique symbols and designs that attract you and other people in the area. This type of stamping often makes your brand something that your customers cannot ignore for too long. They'll see your brand wherever they go in your business and will remember it after they leave. So try to place the stamp in places that the eyes naturally fall. Doing so will make it easier for people to not only see it, but remember it as well. And will help make this process much more effective. The possibilities are endless if you are creative and work hard to make your company stand out. A large number of people often focus on this type of concrete, which makes it a practical and accepted way to brand a company. Just as importantly, you need to focus on creating stamps that are attractive and truly stand out. Too many people many get cheap marks that aren't worth the stamp used to make them. Finding a Spot That Works for You When considering stamped concrete for your business, there are many unique options from which you can pick. However, you need to make sure that you take the time to find a place that works best for your needs. Not every piece of concrete in your facility needs to be stamped to spread your business name. However, you should make sure to find those that make your company as well known as possible. For example, you can stamp the concrete on the sides of your building – if it is made of concrete – to spread your brand. This option is great if you are a large building and you want to attract people to you from a distance. Building stamping is also a healthy idea if you are a smaller business as well because it can ensure that you get the attention that you want from people walking by your company. However, you can also stamp any other items. For example, stamped parking lots are often an excellent idea for those with a large area. You should try to spread your stamps as far as possible without getting too excessive or flashy about it. Often, people will find excessive concrete stamping to be a bit much and may turn away from your business. Remember – taste and restraint are critical for your branding. Talk to Us About This Fascinating Process So if you are interested in the best stamped concrete Dubuque, Coralville, Waterloo, and Cedar Falls, Iowa has to offer you, please contact us at Kelly Concrete today to learn more. Our professionals have years of experience in this field and will do what is necessary to make sure that your concrete is stamped and turns into a great branding opportunity for you and your company.

Pouring high-quality concrete shouldn't be a complicated process, but too many people make mistakes that can complicate the process. Therefore, you need to talk to the best concrete contractors Cedar Rapids, Marion, Iowa City, ad North Liberty, Iowa has to offer to ensure that you fully understand what you need to do to make your concrete the best possible slab that your money can buy. When you do talk to them, ask about the following simple tips and hacks before and after you pour your concrete. Each will provide many benefits that make them more than worthwhile for your needs. Pay attention to when to utilize these simple ideas and implement at least a handful when needed. And always make sure that you talk to your contractors about this process to ensure you get it right. Knowing When and How to Finish Your Concrete A concrete finish helps to protect the surface and interior of your concrete slab and will work hard to ensure that nothing negatively affects your surface for years to come. However, finishing the piece may be tricky if you don't talk to concrete contractors about this process. Too many people may try to add a finish to their concrete before it is time and make the finish ineffective. First of all, you need to wait until all of the water has bled out of your concrete before you do any finishing. This step can be a tricky one because your concrete may hold water longer than you might think. The trick here is that you need to wait until the surface sheen is gone from your concrete. At this point, it is typically ready to get finished because it has lost most of the water. Typically, you're going to want to do a broom finish on most concrete surfaces – this hack is one that too many homeowners don't fully understand. Simply put, a broom provides you with the most accurate and high-quality finishing possible. Unfortunately, troweling and machine floating are often a little too powerful or inaccurate and may cause complications that affect the quality of your pavement. Proper Joint Installation Your concrete slabs need to have high-quality joints installed along their surface to ensure that they can expand and contract with temperature changes. Without these joints, your slab will suffer. However, it can be hard to know when and where to add these joints to your concrete. Some may add too many or too few and cut them at a depth that isn't deep enough to protect your concrete. Here's the basic formula that all concrete contractors use – all of your slabs must be cut to a depth of at least one-quarter the thickness of the piece. Then, each joint must be adequately spaced to create a high-quality slab. For example, if your slab is four inches thick, then you need to cut at least one-inch into the surface at least every 10-12 feet on the slab. This step ensures that your pieces are properly cut. Make sure that you install your joints at the proper time to avoid any complications. Simply put, you must cut them after all the other finishing and curing is finished. This drying wait will make your concrete strong enough to saw without causing any complications. All of your joints must be as straight as possible because crooked or uneven joints won't expand appropriately on your concrete. Avoid Salt for Your First Winter When winter strikes your home and ice builds on your new concrete, you may be tempted to add salt to the surface to melt the snow and ice. This step is understandable, as salt is a powerful anti-ice tool, but is not the right choice after just pouring concrete. Salt has an unfortunate tendency to impact new concrete severely and should be avoided after you pour concrete. Instead, you should add sand to the surface of your concrete to improve traction and melt snow. Sand is much better than salt because it won't cause any scaling on your concrete. While you may want to use salt instead of sand after the first year of your concrete's life, sand is often a much better choice only because it has less chance of damaging your concrete even years down the road. Make sure that you avoid the mistake of using fertilizers on your pavement. Too many concrete contractors have seen their clients make this mistake and have had to help them repair damaged slabs. This step is one that is very easy to avoid if you're smart about how you treat your concrete and take the time to add sand – instead of salt or fertilizer – to your surface. Don't Forget Air Drying Techniques Lastly, you need to make sure that you let your concrete air dry before you add any sealant to its surface. Too many people try to immediately seal their concrete and end up with a mess that doesn't look great and which struggles from a myriad of issues. This mistake is understandable, as these sealants can help to prevent various types of damage, mainly through freezing and thawing. However, you need to wait a few hours before you apply this type of sealant to the surface of your concrete. A good step is to wait at least a full day before you use any sealant. This decision will give your concrete not only the chance to dry but cure as well correctly. At this point, you can check it to make sure that it is durable and hard enough for you to use your sealant correctly. Here's a helpful hack that you should consider for your concrete – the use of fans. Many concrete contractors use high-quality fans to speed up the air curing and drying time of their concrete slabs. Try to keep the flow of air at a reasonable pace and keep the air just above the concrete surface, rather than directly on top. In this way, you can avoid messing up the concrete in any way. Finding Pros Who Understand These Tips As you can see, there are many unique concrete hacks that you can utilize for your home or business. Each of these concepts is something that most contractors fully understand already. As a result, you should make sure that you do significant research and find an expert who knows precisely how to provide this care. So if you're looking for the best concrete contractors that Dubuque, Coralville, Waterloo, and Cedar Falls, Iowa has to offer to provide you with this help, please contact us at Kelly Concrete today to learn more. We can provide you with the support that you need to get the best concrete that your money can afford.

Trying to pour high-quality concrete in Cedar Rapids , Marion, Iowa City, or North Liberty, Iowa can be involved if you don't take the time to understand what causes cracks and how to prevent them. Cracks in your pavement may seem unavoidable in many circumstances and may be impossible to avoid if you lack the skill to identify situations that may lead to severe cracks. The following information is designed to help you better grasp some of the most common contributing factors to the cracked pavement in your driveway. Each section will briefly explain why these cracks occur and what you can do to prevent them. Most of the time, you're going to need professional help to assess this problem and to manage them for you reasonably and professionally. Poor Selection of Materials Many people may assume that concrete is all the same and that they can get the same results from a product no matter what they buy. That is simply not the case. Many types of cement and pavement materials are designed for more decorative items and will crack if you try to use them for driveways or other high-stress situations. You need cement that is designed specifically for the right purpose to avoid cracks on your driveway. For example, you should find bags labeled “for construction use” to ensure your pavement is strong enough to withstand regular use. Just as importantly, you need to make sure that your temperature rating is at the right level to avoid complications. For example, some cement is rated for hot temperatures while others are rated for colder regions. Others are for more general use and adapt based on the temperature circumstances. Adding Too Much Weight Concrete is designed to be strong enough to withstand various elements but can become damaged if you add too much weight to its surface. This problem is typically common along the weaker areas, like the edges of a driveway, and will spread cracks through the surface very quickly. Try to move heavy objects off of your pavement, when possible, or simply redirect concentrated heavy items away from each other. Adding too much weight on one spot can damage your driveway, but moving these items evenly across the surface may prevent many of these common issues. Poor Joint Placement When your pavement is poured, a multitude of joints will be cut into the surface. These joints are designed to give your driveway some room to grow and shrink and should keep your slab in good shape. However, cracks may appear around these joints if they are poorly cut. Typically, you need to have joints that occur according to this formula: multiply the thickness of the slab in inches by 2-3 times to get joint location by feet. For example, if you have five-inch pieces, you'd need joints cut at least every 10-15 feet or so to keep the pavement secure. Extreme Temperature Changes Pavement is typically strong enough to withstand a multitude of temperature changes, but it may experience issues in extreme situations. For example, rapid temperature changes will cause expansion and contraction with the water in your pavement, which may cause cracks to appear. Unfortunately, there isn't much that you can do to avoid this problem if you live in an area with regular temperature changes. However, you can prevent some of this damage by adding a sealant or sealcoat to the surface of your concrete . This step will minimize how much damage the sun and ice can do to your driveway. Poor Drying Management When your pavement is poured and adequately maintained, no cracks should occur in its surface. However, poor drying management could cause complications with how well your pavement settles. For example, the temperature may be a bit too cold, and your pavement may not dry as well as you'd hope. Even worse, there may not be enough moisture in the cement, which can cause it to become too hard or brittle. As a result, the surface may start to crack right away as it dries. In this situation, you need to add more water to your mix and only pour on warm and dry days to avoid complications with your drying. Adding Too Much Water in the Pavement Mix One of the most significant contributing factors to cracked concrete is when you add too much water to the pavement mix. While water is a necessary part of the pouring process, excess water can water down the cement in your pavement and make it less secure. Though this wet pavement will eventually dry and become strong enough to support your vehicles, it will be more prone to damage than other types. As a result, you need to make sure that the water added to your pavement is done so at a reasonable level. Typically, you need one bucket of water per every 10-pound bag of cement. Any more than that and your pavement will come out very watery. If you notice that the mixture has too much water, you can add more cement mixture – a handful at a time – to balance out its thickness a little better. Ground Movement Though you may think that the ground beneath your pavement is relatively stable, this idea is far from reality. The dirt and soil underneath your driveway are likely to go through frequent changes, such as heaving and settling, that can do a real number on your pavement and cause serious cracks. One way to avoid this problem is to remove trees from your yard near the pavement. Tree roots often grow under your pavement and cause a variety of soil problems. You may also need to add more stable dirt underneath your driveway before you pour your pavement to avoid this complication. Help is Available for You As you can see, your pavement is under a lot of pressure and experiences a multitude of problems that can cause cracks. Although these common concerns occur with just about every type of pavement, they can be easily avoided if you know what you are doing. Some individuals get the best results by merely reaching out to professionals who fully understand the needs of their customers. If you need help with cracks in your concrete in Cedar Rapids, Iowa or the surrounding area, please don't hesitate to contact us today to get the help that you need. Our professionals will come to your home or business, inspect the cracks in your pavement, assess what has caused them, and will then take steps to ensure that these cracks never become an issue again.